In the ever-evolving landscape of industries, the manufacturing sector has witnessed a profound transformation through digitization. The term ‘digital transformation’ has become synonymous with innovation, efficiency, and competitiveness. In this article, we delve into the intricacies of how the manufacturing industry has transitioned into the digital era, exploring the drivers, benefits, challenges, and future trends.

Read More: The Future of UK Manufacturing: The Role of Industry 4.0

Key Drivers of Digital Transformation in Manufacturing

Industry 4.0 and Smart Factories

The advent of Industry 4.0 marked a paradigm shift in manufacturing. Smart factories, equipped with interconnected systems and real-time data exchange, have become a cornerstone in the digital evolution.

Integration of IoT in Manufacturing Processes

The Internet of Things (IoT) has played a pivotal role in creating a connected manufacturing ecosystem. From predictive maintenance to supply chain optimization, IoT has revolutionized how manufacturers operate.

Big Data Analytics for Decision-Making

Manufacturers harness the power of big data to gain actionable insights. Analyzing vast datasets allows for informed decision-making, leading to improved efficiency and reduced downtime.

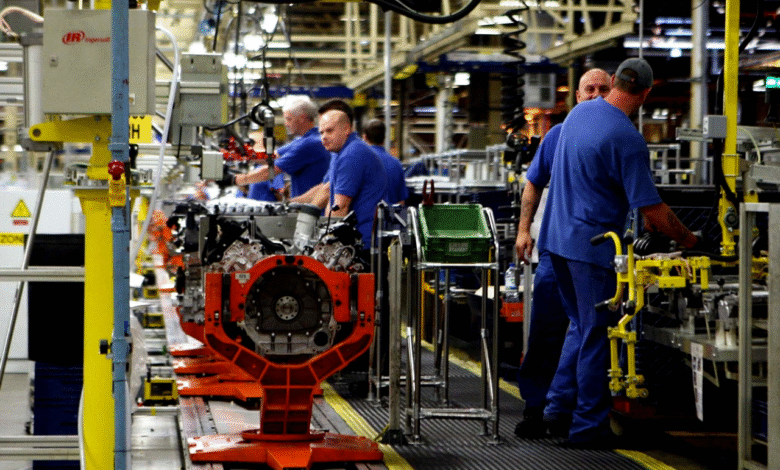

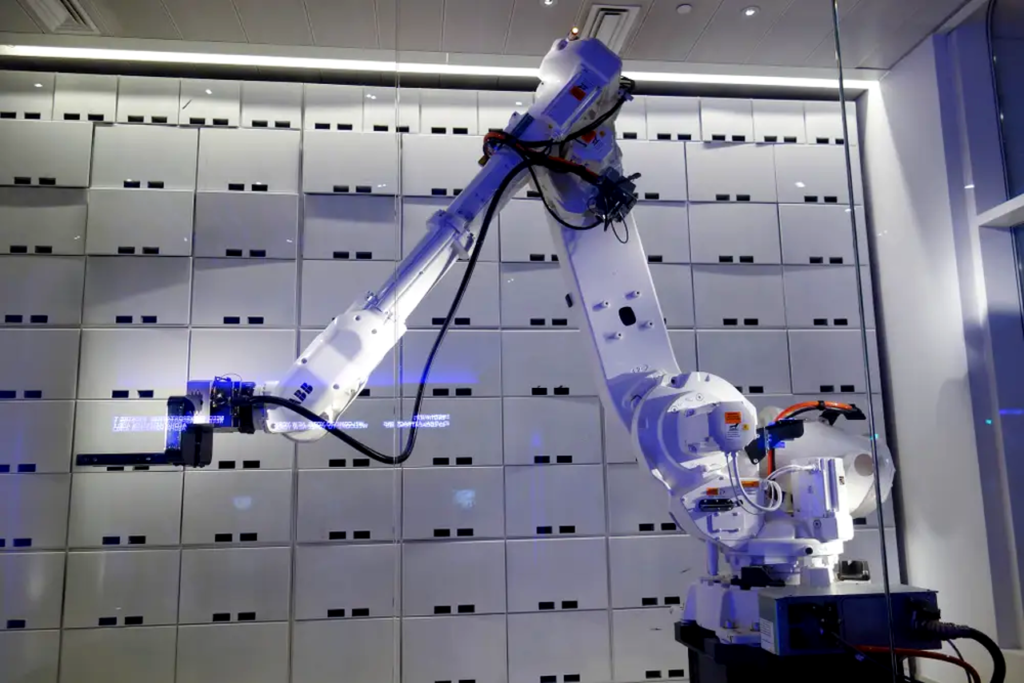

Automation and Robotics Revolution

Automation and robotics have redefined manufacturing processes, enhancing precision, speed, and safety. The integration of robotic systems has become commonplace in modern manufacturing facilities.

Benefits of Digitization in the Manufacturing Industry

Improved Operational Efficiency

Digitization streamlines operations, reducing manual errors and improving overall efficiency. Automation of routine tasks enables a focus on complex, strategic activities.

Enhanced Product Quality

Digital technologies ensure stringent quality control throughout the production cycle. From design to delivery, manufacturers can maintain consistency and produce high-quality products.

Cost Reduction and Resource Optimization

Efficient resource utilization and streamlined processes contribute to cost reduction. Digital technologies enable manufacturers to identify areas for optimization, resulting in substantial savings.

Real-time Monitoring and Predictive Maintenance

Real-time monitoring through sensors and IoT devices allows manufacturers to proactively address issues. Predictive maintenance minimizes downtime, saving both time and resources.

Challenges Faced by the Manufacturing Industry in Going Digital

Initial Implementation Costs

The upfront costs of implementing digital technologies can be a barrier for some manufacturers. However, the long-term benefits often outweigh the initial investment.

Workforce Reskilling and Training

Digital transformation necessitates a skilled workforce. Providing training and reskilling programs ensures that employees can adapt to new technologies seamlessly.

Data Security Concerns

As manufacturing processes become more interconnected, data security becomes a paramount concern. Robust cybersecurity measures are essential to safeguard sensitive information.

Integration of Legacy Systems

Many manufacturing facilities still operate with legacy systems. Integrating these systems with modern technologies can be a complex process, requiring careful planning.

Case Studies: Successful Digital Transformations in Manufacturing

Company A: Implementing IoT for Smart Manufacturing

Company A embraced IoT to create a smart manufacturing environment. By connecting machines and systems, they achieved real-time monitoring, predictive maintenance, and data-driven decision-making.

Company B: Harnessing Big Data for Enhanced Decision-Making

Company B utilized big data analytics to optimize its production processes. Analyzing large datasets helped them identify patterns, improve efficiency, and make informed decisions.

Company C: Achieving Automation Excellence

Automation became the focal point for Company C. By integrating robotic systems into their production line, they significantly increased productivity while maintaining product quality.

Future Trends in Digital Transformation for Manufacturing

Artificial Intelligence and Machine Learning Integration

The integration of AI and machine learning is set to play a pivotal role in manufacturing. From predictive analytics to autonomous systems, AI will drive innovation in the industry.

3D Printing Revolutionizing Production Processes

3D printing is disrupting traditional manufacturing methods. It offers cost-effective prototyping, customization, and on-demand production, revolutionizing how products are manufactured.

Blockchain for Supply Chain Transparency

Blockchain technology enhances transparency in the supply chain. Manufacturers can trace the origin of raw materials, ensuring quality and compliance throughout the production process.

Sustainability and Green Manufacturing Initiatives

The future of manufacturing involves a commitment to sustainability. Green manufacturing practices, such as renewable energy adoption and waste reduction, will become integral to the industry.

Tips for Manufacturers Embracing Digital Transformation

Develop a Comprehensive Digital Strategy

Manufacturers should outline a clear digital strategy that aligns with their business goals. This strategy should encompass technology adoption, employee training, and long-term objectives.

Invest in Employee Training and Development

The success of digital transformation relies on a skilled workforce. Investing in continuous training and development programs ensures that employees can effectively utilize new technologies.

Ensure Cybersecurity Measures

With the increasing connectivity of manufacturing processes, cybersecurity is paramount. Manufacturers should implement robust measures to protect sensitive data from cyber threats.

Collaborate with Technology Partners

Collaborating with technology partners can provide manufacturers with valuable insights and expertise. Building partnerships can accelerate the digital transformation journey.

Overcoming Resistance to Change in the Manufacturing Sector

Communicating the Benefits of Digital Transformation

Clear communication regarding the benefits of digital transformation is essential. Manufacturers should articulate how it improves efficiency, reduces costs, and enhances competitiveness.

Involving Employees in the Decision-Making Process

Including employees in the decision-making process fosters a sense of ownership and reduces resistance. Their input can provide valuable perspectives and contribute to successful implementation.

Providing Continuous Support and Feedback

Continuous support and feedback mechanisms are crucial during the transition. Addressing concerns and providing ongoing assistance ensures a smoother adoption of digital technologies.

IRealizing the Potential: Success Stories in Digitally Transformed Manufacturers

Highlighting real-world success stories emphasizes the tangible benefits of digital transformation. These stories serve as inspiration and provide practical insights for other manufacturers on their journey.

The Future Landscape: What to Expect in the Digital Manufacturing Evolution

The future holds exciting prospects for digital manufacturing. From further advancements in AI and robotics to sustainable practices, manufacturers need to stay agile to embrace the evolving landscape.

Read More: How UK Businesses are Embracing Automation and Robotics

The Final Words

The digital transformation of the manufacturing industry is not a choice but a necessity for survival in a competitive global market. Embracing digitization offers unparalleled opportunities for efficiency, innovation, and sustainability. Manufacturers must navigate challenges with resilience and continually evolve to stay at the forefront of the digital revolution.