Electric bikes have transformed the way we think about cycling and urban transportation. At the heart of every e-bike lies its motor system, which determines how the bike performs, feels, and handles different riding conditions. Understanding electric bike technology is crucial for anyone considering purchasing an e-bike or simply curious about how these innovative machines work.

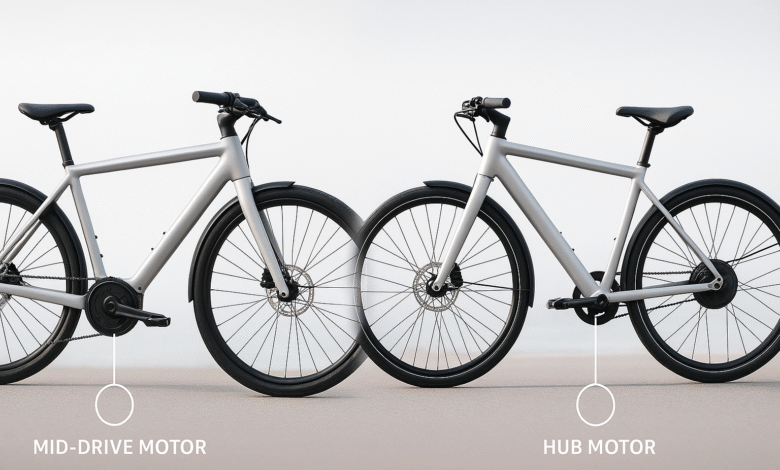

The two main types of electric bike motors are mid-drive and hub motor systems. Each offers distinct advantages and characteristics that make them suitable for different riding styles and preferences. This comprehensive guide will explore both systems in detail, helping you understand which technology might be the best fit for your needs.

Understanding Electric Bike Motor Systems

Electric bike technology has evolved significantly since the first e-bikes appeared on the market. Modern e-bike motors are sophisticated pieces of engineering that seamlessly blend human power with electric assistance. The motor system includes not just the motor itself, but also the battery, controller, and various sensors that work together to provide a smooth and efficient riding experience.

The fundamental difference between mid-drive and hub motors lies in their placement on the bike. This positioning affects everything from the bike’s balance and handling to its efficiency and maintenance requirements. Both systems have their place in the e-bike market, serving different types of riders and riding conditions.

When evaluating electric bike technology, it’s important to consider factors such as power delivery, efficiency, weight distribution, and overall riding experience. The motor system you choose will significantly impact how your e-bike performs on hills, how it handles in different weather conditions, and how much maintenance it will require over time.

What Are Mid-Drive Motors?

Mid-drive motors, also known as central motors, are positioned at the bike’s bottom bracket, where the pedals connect to the frame. This central location gives mid-drive systems several unique characteristics that distinguish them from other electric bike technology options.

The design of mid-drive motors allows them to work directly with the bike’s existing drivetrain. When you pedal, the motor adds power to your pedaling effort through the bike’s chain and gears. This integration means that mid-drive motors can take advantage of the bike’s gear ratios, making them particularly effective on hills and varied terrain.

Mid-drive systems typically offer more natural-feeling assistance because they amplify your pedaling input rather than simply providing additional thrust. The motor engages when it detects pedaling motion and adjusts its output based on how hard you’re pedaling and what assistance level you’ve selected.

Most mid-drive motors use torque sensors to measure how much force you’re applying to the pedals. This sensor technology allows the motor to provide proportional assistance, creating a riding experience that feels more like riding a traditional bike with enhanced capabilities rather than riding a motorized vehicle.

Advantages of Mid-Drive Systems

Mid-drive motors offer several compelling advantages that make them popular among serious cyclists and those who frequently ride in challenging terrain. The central motor placement creates excellent weight distribution, keeping the bike’s center of gravity low and maintaining natural handling characteristics.

The ability to utilize the bike’s gears gives mid-drive systems a significant advantage in efficiency and climbing ability. When tackling steep hills, you can shift to lower gears, allowing the motor to operate in its most efficient range while providing maximum torque to the rear wheel.

Mid-drive motors generally provide better traction, especially in wet or loose conditions. Since the motor drives the rear wheel through the chain, the weight of the rider and bike helps keep the rear wheel planted, reducing the likelihood of wheel spin.

Battery life tends to be better with mid-drive systems because the motor can operate more efficiently across different riding conditions. The ability to use gears means the motor doesn’t have to work as hard to maintain speed or climb hills, resulting in lower power consumption.

Disadvantages of Mid-Drive Systems

Despite their advantages, mid-drive systems have some drawbacks that potential buyers should consider. The integration with the drivetrain means that mid-drive motors put additional stress on the chain, cassette, and other drivetrain components, potentially leading to increased wear and more frequent maintenance.

Mid-drive bikes are often more expensive than comparable hub motor bikes, both in initial purchase price and long-term maintenance costs. The complex integration with the bike’s drivetrain requires more sophisticated engineering and manufacturing processes.

Some riders find that mid-drive motors can be noisier than hub motors, particularly under heavy load or when climbing hills. The sound comes from the motor working through the bike’s chain and gears, which can amplify operational noise.

Installation and repair of mid-drive systems typically require more specialized knowledge and tools compared to hub motors. This can make DIY maintenance more challenging and may require visits to specialized e-bike shops for service.

What Are Hub Motors?

Hub motors are integrated directly into either the front or rear wheel of the bike, replacing the standard wheel hub. This electric bike technology approach puts the motor at the point where power is delivered to the ground, creating a direct-drive system that doesn’t rely on the bike’s drivetrain.

There are two main types of hub motors: geared and direct-drive. Geared hub motors use internal gears to reduce the motor’s RPM while increasing torque, making them more efficient at lower speeds. Direct-drive hub motors have no internal gears and rely on electromagnetic force alone to turn the wheel.

Hub motors can be positioned in either the front or rear wheel, with each placement offering different characteristics. Front hub motors provide a pulling sensation and can create an all-wheel-drive effect when combined with pedaling. Rear hub motors offer a pushing sensation that many riders find more natural and familiar.

The operation of hub motors is generally simpler than mid-drive systems. When you activate the motor through the throttle or pedal-assist system, the motor directly rotates the wheel, providing immediate power delivery without going through the bike’s drivetrain.

Advantages of Hub Motor Systems

Hub motors offer several advantages that make them attractive to many e-bike riders. The simplicity of the design typically results in lower maintenance requirements since the motor operates independently of the bike’s drivetrain components like the chain and gears.

Installation and replacement of hub motors is generally more straightforward than mid-drive systems. The motor is contained within the wheel, making it easier to swap out or service when necessary. This simplicity also tends to make hub motor bikes less expensive than comparable mid-drive options.

Hub motors often provide smoother and quieter operation, especially direct-drive versions. Without the need to work through gears and chains, the power delivery can be more seamless and less audible during operation.

The independent operation of hub motors means they don’t add stress to the bike’s drivetrain components. Your chain, cassette, and derailleur will experience normal wear rates, potentially reducing long-term maintenance costs and extending component life.

Many hub motor systems offer throttle control, allowing you to engage the motor without pedaling. This feature can be particularly useful when starting from a stop, navigating traffic, or when you need a break from pedaling.

Disadvantages of Hub Motor Systems

Hub motors also have limitations that riders should consider. The weight distribution can be less ideal than mid-drive systems, particularly with rear hub motors that add significant weight to the back of the bike. This can affect handling and make the bike feel less balanced.

Hill climbing performance is generally not as strong as mid-drive systems because hub motors cannot take advantage of the bike’s gear ratios. The motor must work harder to maintain power output on steep inclines, which can lead to overheating and reduced efficiency.

Wheel removal for flat tire repairs can be more complicated with hub motors due to the electrical connections and the weight of the motor. This can make roadside repairs more challenging and time-consuming.

Hub motors, particularly in the front wheel, can affect the bike’s steering and handling characteristics. The added weight and gyroscopic effects of the spinning motor can make the bike feel different compared to a traditional bicycle.

Performance Comparison: Mid-Drive vs Hub Motors

When comparing electric bike technology options, performance characteristics play a crucial role in determining which system best suits your needs. Mid-drive and hub motors excel in different areas, making the choice dependent on your specific riding requirements and preferences.

Climbing performance represents one of the most significant differences between these systems. Mid-drive motors leverage the bike’s gear ratios to maintain efficiency and power output on steep inclines. By shifting to lower gears, the motor can operate in its optimal RPM range while delivering maximum torque to the rear wheel. Hub motors, conversely, must rely on their fixed gear ratio and may struggle on extended climbs, potentially overheating under sustained high loads.

Acceleration characteristics also differ between the two systems. Hub motors often provide more immediate power delivery, especially when using throttle control. The direct connection to the wheel means instant response when power is applied. Mid-drive motors may have a slight delay as power transfers through the drivetrain, but they often provide more natural-feeling acceleration that matches your pedaling cadence.

Range and efficiency vary significantly between motor types and depend heavily on riding conditions. Mid-drive systems typically offer better efficiency on varied terrain because they can maintain optimal motor RPM through gear changes. Hub motors may be more efficient on flat terrain and at consistent speeds but can consume more battery power on hills or during frequent acceleration and deceleration.

Speed capabilities depend on the specific motor and bike design rather than the motor type alone. Both mid-drive and hub motors can be designed for various speed ranges, though the power delivery characteristics differ. Mid-drive motors often provide better sustained high-speed performance due to their ability to use higher gears.

Weight Distribution and Handling

The placement of the motor significantly impacts how an e-bike handles and feels during riding. Electric bike technology designers must carefully consider weight distribution to maintain the natural riding characteristics that cyclists expect while adding the benefits of electric assistance.

Mid-drive motors create the most balanced weight distribution by placing the heaviest component at the bike’s center of gravity. This central placement maintains the bike’s natural handling characteristics and keeps the weight low, contributing to stability and maneuverability. The bike feels more like a traditional bicycle, just with enhanced power.

Front hub motors place significant weight in the front wheel, which can affect steering feel and handling. The added weight can make the steering feel heavy at low speeds and may create a gyroscopic effect that influences how the bike tracks and turns. However, front hub motors can provide beneficial traction in certain conditions and create an all-wheel-drive effect when combined with rear-wheel pedaling power.

Rear hub motors add weight to the back of the bike, which can make the rear end feel heavy and may affect how the bike handles in certain situations. The weight bias toward the rear can impact climbing performance by reducing front wheel traction and may make the bike feel less nimble in tight turns or technical riding situations.

The impact of motor placement becomes more noticeable as motor size and weight increase. Smaller, lighter motors of any type have less impact on handling, while larger, more powerful motors can significantly change how the bike feels and responds to rider input.

Battery Life and Efficiency

Battery performance and efficiency are critical aspects of electric bike technology that directly affect the practical usability of your e-bike. The type of motor system you choose can significantly impact how far you can ride on a single charge and how efficiently the system uses stored energy.

Mid-drive motors generally offer superior efficiency because they can leverage the bike’s gear ratios to maintain optimal operating conditions. When climbing hills, the rider can shift to easier gears, allowing the motor to spin at its most efficient RPM while still providing adequate power to the rear wheel. This efficient operation translates to longer battery life and extended range.

Hub motors operate at a fixed gear ratio, which means they must adjust their power output and RPM based on riding conditions without the benefit of mechanical advantage from gears. On flat terrain and at consistent speeds, hub motors can be quite efficient. However, they typically consume more power during hill climbing or frequent acceleration and deceleration cycles.

Riding style significantly impacts battery life regardless of motor type. Aggressive acceleration, frequent hill climbing, and higher assistance levels will drain the battery more quickly with any system. However, mid-drive systems tend to be more forgiving of varied riding styles due to their ability to maintain efficiency across different conditions.

Environmental factors such as temperature, wind, and terrain also affect battery performance. Cold weather reduces battery capacity, while headwinds and hilly terrain increase power consumption. Mid-drive systems typically handle these challenging conditions more efficiently, helping to maximize range even in less-than-ideal circumstances.

Regenerative braking capabilities vary between motor types and specific implementations. Some hub motors, particularly direct-drive versions, can recover energy during braking or descending hills. This feature can extend range in certain riding conditions, though the energy recovery is typically modest compared to the total energy consumption.

Also Read: Electric Cars Review: Which EV Offers the Best Value in the UK?

Maintenance and Durability

The maintenance requirements and long-term durability of electric bike technology vary significantly between mid-drive and hub motor systems. Understanding these differences is crucial for making an informed decision about which system best fits your mechanical aptitude and maintenance preferences.

Mid-drive motors integrate with the bike’s drivetrain, which means they share the mechanical stresses of power transmission with the chain, cassette, and derailleur. This integration can lead to accelerated wear of these components, particularly the chain, which must handle both human and motor power. High-quality chains designed for e-bike use can help mitigate this issue, but replacement intervals may be shorter than with traditional bikes.

The complexity of mid-drive systems can make diagnosis and repair more challenging. When problems occur, it may require specialized knowledge to determine whether the issue lies with the motor, controller, sensors, or integration with the drivetrain. This complexity often necessitates visits to specialized e-bike shops for major repairs or maintenance.

Hub motors operate independently of the bike’s drivetrain, which means they don’t add stress to chains, gears, or derailleurs. The motor is essentially a sealed unit within the wheel, providing protection from dirt, water, and other environmental contaminants. This isolation often results in lower maintenance requirements and fewer points of failure.

However, hub motor maintenance can present unique challenges. Wheel removal for tire changes or spoke replacement requires disconnecting electrical connections and handling the weight of the motor. The motor’s integration into the wheel can also make certain types of wheel service more complex or require specialized tools.

Both motor types benefit from regular cleaning and inspection of electrical connections. Keeping the motor and controller dry and clean helps ensure long-term reliability. Most quality e-bike motors are designed to handle normal weather conditions, but prolonged exposure to extreme conditions can affect performance and longevity.

Cost Considerations

The financial aspects of electric bike technology extend beyond the initial purchase price to include long-term ownership costs, maintenance expenses, and potential upgrade considerations. Understanding the complete cost picture helps in making an informed decision between mid-drive and hub motor systems.

Initial purchase prices typically favor hub motor systems, which are generally less expensive to manufacture and integrate into complete bikes. The simpler design and installation process often translate to lower retail prices, making hub motor e-bikes more accessible to budget-conscious buyers. However, the price gap between motor types has narrowed as manufacturing volumes have increased and technology has matured.

Mid-drive systems command premium prices due to their more complex engineering and manufacturing requirements. The integration with the bike’s drivetrain requires precise engineering and often involves licensing agreements with motor manufacturers. These factors contribute to higher initial costs but may be justified by improved performance and efficiency.

Long-term maintenance costs can vary significantly between motor types. Mid-drive systems may require more frequent drivetrain component replacement due to the additional stress placed on chains and cassettes. However, the improved efficiency and performance may offset these costs through better battery life and overall system longevity.

Hub motor systems typically have lower drivetrain maintenance costs since the motor operates independently. However, any motor repairs or replacements can be more expensive due to the integration with the wheel. Additionally, the inability to take advantage of gear ratios may lead to higher battery replacement costs over time due to less efficient operation.

Upgrade potential and compatibility should also be considered in cost calculations. Hub motors are often easier to retrofit to existing bikes, potentially allowing you to convert a traditional bike to electric. Mid-drive conversions are possible but typically more complex and expensive.

Choosing the Right System for Your Needs

Selecting the appropriate electric bike technology depends on carefully evaluating your riding style, terrain, performance expectations, and practical considerations. Both mid-drive and hub motor systems have their place in the e-bike market, serving different types of riders and use cases effectively.

For riders who frequently encounter hills, varied terrain, or long distances, mid-drive systems often provide the best overall experience. The ability to leverage gear ratios for efficient climbing and the generally superior battery life make mid-drive motors excellent choices for commuting, touring, or recreational riding in challenging conditions.

Urban commuters who primarily ride on flat terrain with occasional hills might find hub motors perfectly adequate and more cost-effective. The simplicity of operation, lower maintenance requirements, and often lower purchase price make hub motors attractive for practical transportation needs.

Mountain bikers and performance-oriented cyclists typically prefer mid-drive systems for their natural feel, excellent weight distribution, and superior climbing ability. The integration with the bike’s drivetrain provides the most bike-like experience while adding significant power assistance.

Casual riders who want simple, reliable transportation might gravitate toward hub motor systems. The ease of use, lower maintenance requirements, and often included throttle control can make cycling more accessible and enjoyable for those who aren’t interested in the technical aspects of cycling.

Consider your mechanical aptitude and access to service when making your decision. If you prefer to handle your own maintenance and repairs, hub motors might offer advantages due to their simpler design. If you have access to good e-bike service or prefer professional maintenance, the choice between motor types becomes less critical from a service perspective.

Future Trends in Electric Bike Technology

The electric bike technology landscape continues to evolve rapidly, with innovations in motor design, battery technology, and system integration promising to enhance the e-bike experience further. Understanding these trends can help inform your purchasing decision and provide insight into what the future holds for electric cycling.

Motor efficiency improvements are ongoing across both mid-drive and hub motor designs. Manufacturers are developing more sophisticated controller algorithms, better sensor technology, and improved motor designs that deliver more power while consuming less energy. These improvements benefit both motor types and help extend range and performance.

Integration between motor systems and other bike components continues to advance. Smart systems that communicate between the motor, battery, drivetrain, and even smartphone apps provide riders with unprecedented control and information about their bike’s performance and status. These connected systems promise to enhance the riding experience and provide valuable data for optimizing performance.

Battery technology improvements are perhaps the most significant factor in the evolution of electric bike technology. Higher energy density batteries provide longer range without additional weight, while faster-charging capabilities reduce downtime between rides. Improved battery management systems also extend battery life and provide better protection against damage.

The line between mid-drive and hub motor systems may continue to blur as manufacturers develop hybrid approaches and new motor placement strategies. Some companies are experimenting with dual-motor systems that combine the benefits of both approaches, while others are developing new motor designs that address traditional limitations of each type.

Conclusion

Understanding electric bike technology and the differences between mid-drive and hub motor systems is essential for making an informed e-bike purchase decision. Both technologies offer distinct advantages and serve different riding needs effectively.

Mid-drive motors excel in efficiency, climbing performance, and providing a natural cycling feel through their integration with the bike’s drivetrain. They’re ideal for riders who frequently encounter varied terrain, prioritize performance, or want the most bike-like experience from their e-bike.

Hub motors offer simplicity, lower maintenance requirements, and often more affordable pricing. They work well for urban commuting, casual riding, and situations where ease of use and reliability are priorities over maximum performance.

The choice between these electric bike technology options ultimately depends on your specific needs, riding style, and preferences. Consider factors such as your typical riding terrain, performance expectations, maintenance preferences, and budget when making your decision.

As the e-bike market continues to mature and technology advances, both mid-drive and hub motor systems will likely continue to improve and find their respective niches. The most important factor is choosing a system that matches your needs and encourages you to ride more often, regardless of which technology powers your journey.